Self regulating heating cables that automatically adjust their power output to compensate for temperature changes. Self regulate heat trace cables are the advance technology in electric heating cables. They are designed and manufacture to regulate their output according to process temperature i.e. as the process temperature go down , the cable’s output increases; opposite, as the temperature rises, the cables output decreases. Self regulating heating cable contain a polymer core extruded onto two parallel conductors. The core consist semi-conductive material that is high in carbon content usually “graphite”, which allows electricity to flow from one bus wire to the other and create infinitely parallel resistors. The core’s resistance changes proportionally with temperature changes and the output varies along the length of the cable depending upon the temperature of the core of the heater. The fundamental principle of operation is that “when the temperature of the core increases or decreases, a change in the chemical composition takes place, which results in a increase decrease resistance and more or less heat output watt. This self regulating properties allows the cable to adjust its watt output at any point along the entire length of the heater circuit, helping to remove warm or cold spots.

Self Regulating Heating Cable

| Maximum Maintenance Temperature energized | 250 °C |

| Maximum Exposure Temperature, de-energized | 250 ° C |

| Maximum Circuit Length | 154 M |

| Maximum Out Put Power@10 deg C | 75 W/M |

| T Class | T3 |

| Nominal Voltage: | 230 V AC |

| Features |

|

Advantages

|

After its inception in 1971, Self-regulating heat trace cables have become mainstream in the prospect of heat tracing cables used around the globe. Our experts here at Pak Link Services have selected the best Heating cables for you, both in terms of functionalities and designs. With the flexibility that is easily stretchable to being heat resistant in complex piping areas, we have it all!

Pak Link services are one of the most sought-out self-regulating heat trace cables providers in the Middle East and Central Africa. We are considered as one of the top providers of heat tracing technology that are superior to other products presently available in this domain.

These cables have a variety of uses. From ensuring freeze protection of pipework and vessels to implementing process temperature maintenance, they have it all! Moreover, they are also exceptional in heating roads, walkways, ramps, etc. While their ability to ensure roof and gutter heating is stupendous as well.

Functionalities

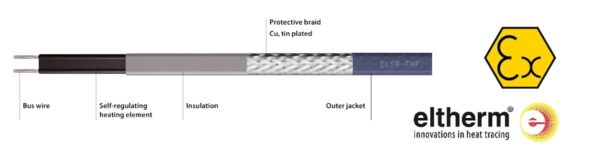

The self-regulating cables from Pak Link Services have a tinned copper braid, coupled with a polyolefin external jacket that provides grounding (it did not provide grounding) and added mechanical protection. We also have a fluoropolymer jacket available, if you want environmental protection in your arsenal.

Moreover, these heat tracing cables comprises of a conductive-polymer heating matrix situated between two parallel copper bus conductors. Heat is conducted in the matrix, while the bus conductors provide similar voltage across the matrix along the total length of the cable.

When the temperature increases, the electrical paths in the heating matrix becomes longer; hence, increasing the resistance of the heating element. In doing so, the heat output decreases; thus, creating a self-regulating effect.

On top of that, our heat tracing cables operate under the necessary ISO standard for high-quality results. So, if you want a trustworthy provider of heat tracing cables, then Pak Link Services are here for you?

Simple to Design

Our experts here at Pak Link Services do not work according to the magnitude of the project. All projects are large-scale for us! Nonetheless, our heat tracing cables are not only easy to design, but we also provide a step-to-step guide that can help you determine the heating requirements.

Easy Installation

Our heat tracing cables are directly installed on metallic (or non-metallic) piping with the influence of conventional thermal insulation. We provide kits for power connection, end termination as well as splicing. Summing up for you is an easy installation with long-term benefits.

All you have to do is simply pull the cable from the supply reel, install it directly on the pipe and finish the circuit Installation (fabrication). You can further install the tee splices, Junction boxes, anywhere along the circuit to match the layout for piping.